PICK UP

Automated Warehouse

Automated Warehouse

Automated Warehouse

Related manufacturer:IHI Logistics & Machinery Corporation

Achieve space saving, labor saving, and accurate inventory management all at once!

Features

- Significant reduction in storage space

Multi-level storage with integrated racks and cranes makes full use of the space up to the ceiling, making the most of your current space. - Easy to use and labor-saving

Operation is one-touch with a touch panel or barcode reader, and loading and unloading operations are fully automated.

This reduces the amount of work required, such as searching, walking, and taking things out. As a result, one person can operate multiple cranes, significantly reducing labor needs. - Easy and accurate inventory management

The key to warehouse operations is loading and unloading and inventory management. Traditionally, reliable inventory management required an experienced, dedicated person, but with an automated warehouse, anyone can manage inventory easily and accurately using a computerized inventory system. - It's now common sense: first in, first out

The automated warehouse is linked to computerized inventory information and automatically performs first-in, first-out, minimizing damage to goods and the need to switch between goods. - Improved safety and working environment

The storage space and the space where people can enter are completely separated, further increasing safety.

Moreover, since loading and unloading is automatic, there are no mistakes and fatigue is greatly reduced, further improving the working environment.

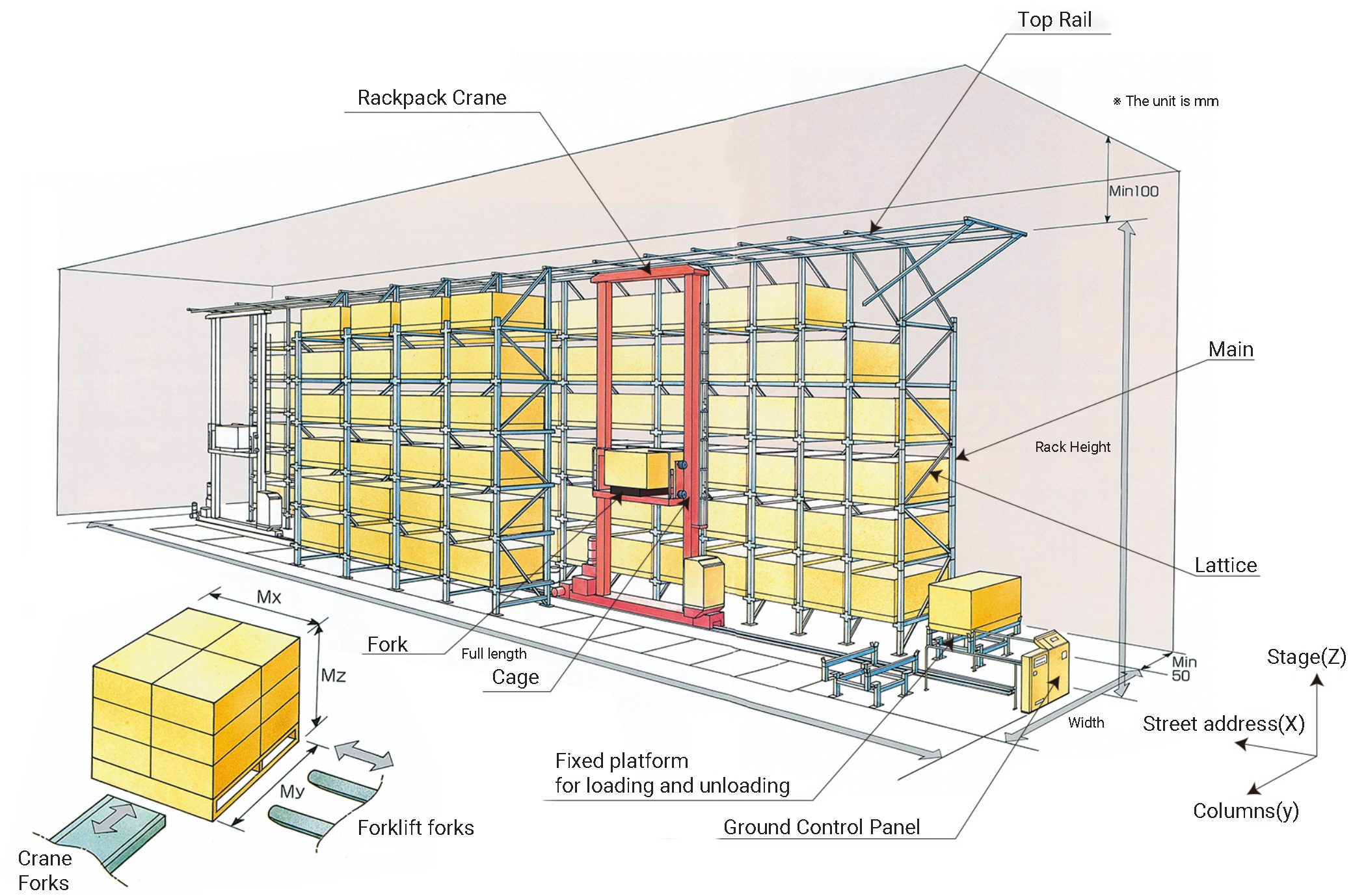

Structure of the automated warehouse

PRODUCT

Product introduction

Pallet Automated Warehouse

Rack Pack® Building-type automated warehouse

Auto Stack Building Automatic case warehouse

RoboStack®

Rack Pack® Building-type automated warehouse

Auto Stack Building Automatic case warehouse

RoboStack®

Pallet Automated Warehouse

Rack Pack®

Quick access makes it easy on the items. More storage space.

Anyone can use it, making it economical.

Features

- Slim & compact

We have thoroughly reviewed the basic structure to reduce waste. The weight is approximately 30% lighter than our previous cranes, and the rack is approximately 10% lighter.

Furthermore, by slimming down the crane, the installation space has become more compact, allowing for more effective use of limited space. - Fast & Smooth

Equipped with IHI's unique Trapezoid Acceleration System (I-TAS) (patent pending).

The system uses a cargo-friendly control system that enables smoother, faster loading and unloading of cargo in a short time while minimizing swaying.

In addition, a servo motor is used to drive the forks, achieving high speed and preventing load shifting at the same time. The shaking during acceleration and deceleration of the crane is controlled to a minimum.

It allows for smooth transport that is gentle on the load, so that even a glass filled to the brim with water can be transported without spilling a drop. - Energy saving & eco-friendly

Equipped with a power regeneration function as standard. Compared to conventional products, it saves energy and reduces unnecessary heat generation. Furthermore, if a capacitor (optional) is installed, it is possible to effectively use regenerative power and reduce peak power consumption, and even greater energy savings can be expected.

Building-type automated warehouse

Auto Stack Building

An integrated automated warehouse boasting top-class performance

Features

- Achieves high space saving

By integrating the steel rack frame of an automated warehouse with the building structure (foundation, walls, roof, etc.), the dead space between the rack and the building can be reduced. - Secures high advantages in terms of cost, construction time, and storage efficiency

By making the racks taller, we can ensure higher storage efficiency compared to modular automated warehouses that are separated from the building. In addition, because the building and racks are integrated into a single structure, fewer building materials are required compared to modular warehouses, which generally reduces overall cost and construction time. - IHI's Total Engineering

IHI handles everything from building design and construction to equipment manufacturing.

Case Studies

-

Auto Stack Building

-

Auto stack building for completed vehicles

-

Auto stack building for freezing

Automatic case warehouse

RoboStack®

Compatible with buckets, cartons, and cases! IHI Robostack Series

Features

- Vibration Control

Shaking during acceleration and deceleration of the crane is controlled to a minimum, achieving smooth movement that is gentle on the load. - Quiet

Along with the aluminum rails, urethane wheels are used for the running wheels, achieving extremely quiet operation. - High stopping accuracy

A laser range finder is used to determine the position of travel and lifting. Real-time distance measurement provides extremely high stopping accuracy. - Multiple packaging options available

Our lineup includes side clamp and twin fork types, allowing us to handle a wide range of packages, large and small.

Case Studies

-

Trolley (lifting section)

-

Aluminum rail,

Urethane wheels (running part) -

Laser range finder (traveling part)

-

Laser range finder (Lifting section)