Improve the durability of metal parts

for precision equipment without compromising design

Succeeded in one-step integral molding, something that was previously thought to be impossible

PROPOSER

Our customers are the manufacturing companies that support Japan.

We provide precision molded parts and metal parts.

We are often contacted from the development stage onwards,

and we handle a wide range of needs, from design proposals to mass production.

BEGINNING

The metal parts of a precision instrument were not strong enough and durability was an issue.

When we visited the customer to discuss their concerns, they consulted us and the project started.

In order to maintain the design, a special shape was necessary.

The precision equipment manufactured by our client faces fierce competition in the market, so they place great importance on design as a differentiation strategy.

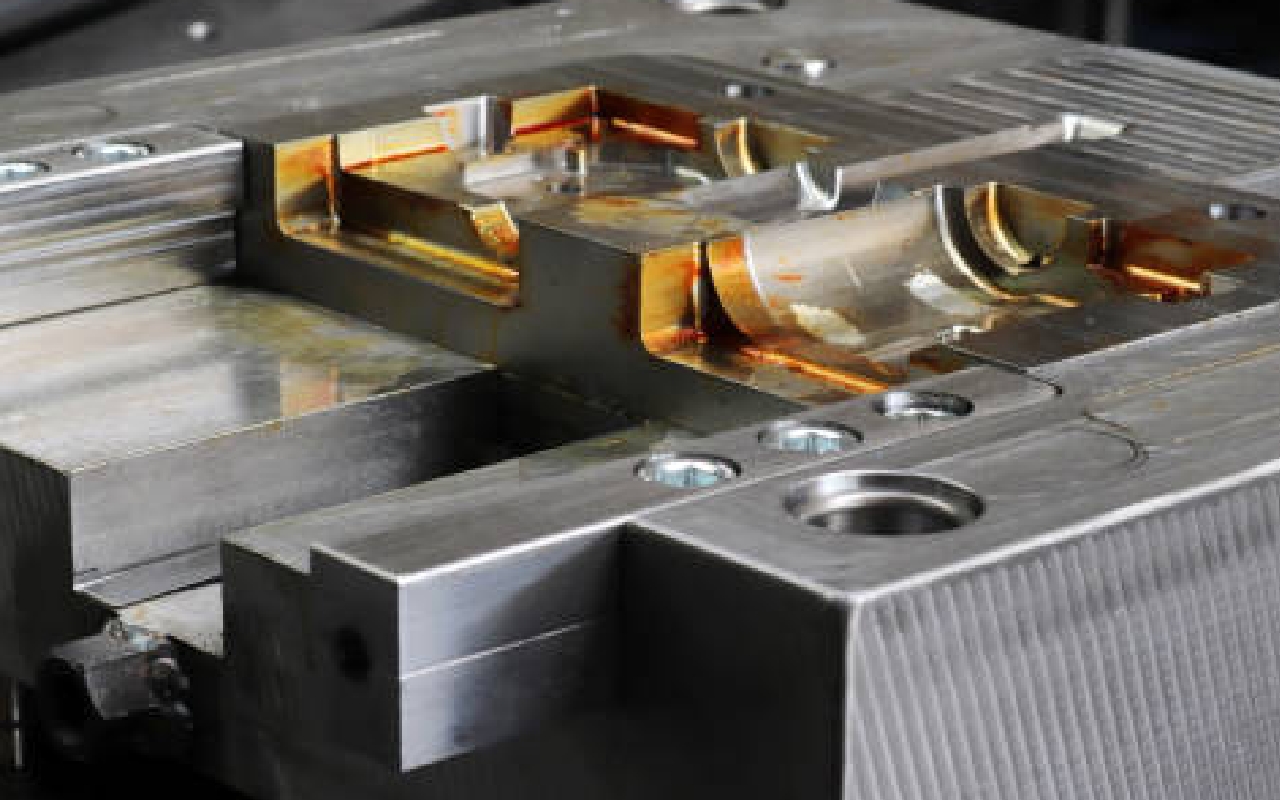

For this reason, one metal part had to be specially shaped despite being subjected to force, and a method of welding two types of pressed parts together was used, despite the high costs.

This part was welded, so the strength of the welds was inevitably insufficient, which affected the overall durability of the equipment.

In addition, because it requires a total of three processes, two press processes and one welding process, it is more expensive than regular pressed parts.

This part posed major challenges for this product due to both its lack of strength and its high cost.

NETWORK

How to process the shape

in one press

After carefully considering the metal materials and various press processes, the customer had no choice but to choose the current two-part joining method.

The challenge is how to process it in one press.

After repeated discussions with my superiors and the technical department, and consulting with our partner press manufacturer, we considered how to process the part in one press and decided on a plan.

If we give up now, we will be feeling sorry for our customers who trusted us and consulted us.

SOLUTION

Instead of giving up because you can't do it, think about how you can do it.

At first, the press manufacturer was not confident, but after repeated prototypes, they began to feel confident about the mold design, and after more than six months, they were finally able to complete a prototype that was acceptable to the customer. Thanks to the cooperation of our customers, we were able to make multiple prototypes, which is why we were able to succeed in one-step molding, something that was previously thought to be impossible.

The solution to this problem using this press was highly praised by the customer, and we received an award as an excellent example of an improvement proposal.

We are grateful to the press manufacturer who never gave up and worked with us through the development to the very end.

I will continue to keep this spirit in mind and continue until I can solve any problem, no matter how difficult it may be.