Upgrading laser oscillators

while utilizing existing equipment

Our original optical design proposals allow you to update only the equipment you need.

PROPOSER

In the Laser Division, our engineers propose products that meet the needs of each customer's laser application and processing conditions (materials, processing quality, tact time, cost, etc.), and deliver laser-related equipment to customers. We propose optimal laser products based on our unique optical designs to meet our customers' needs.

BEGINNING

One of our customers, an automobile manufacturer, wanted to upgrade their laser oscillator from an old YAG laser to a fiber laser in order to improve the efficiency of the laser welding process and reduce running costs in their production lines.

Since the specifications of the laser oscillators are different, all the laser manufacturers proposed updating the entire system, including the processing head and fiber mounted on the robot, by updating the laser oscillator.

This resulted in high equipment renewal costs, making it difficult to decide to implement the system.

We visited the company to promote our company's ability to propose laser-related equipment from the optical design stage onwards, and were given the opportunity to make this proposal, which led to the start of the project.

Is it possible to reduce the investment cost of the entire system by updating the laser oscillator more?

The customer had a large number of laser welding devices in operation on their manufacturing line, and each of the devices had been installed for a certain amount of time. In the future, it will be necessary to upgrade the laser welding equipment as a preventive maintenance measure.

Laser equipment is evolving day by day, and in recent years, fiber lasers, which have high conversion efficiency and low running costs, have become mainstream. The customer's manufacturing line was almost entirely equipped with old YAG lasers, so they were considering changing to fiber lasers when updating their equipment. When the customer consulted with several laser manufacturers, all they offered were plans to completely renew the downstream system, including the processing head, which was the existing equipment, and the estimates for updating the laser oscillator per unit were extremely high.

Therefore, they asked us to make a proposal to reduce the implementation cost.

TECHNOLOGY

Unique optical system design technology required

In order to shorten the process, remote laser welding, which realizes processing speeds seven times faster than resistance welding, is used on the customer's manufacturing line. However, the optical equipment for laser welding is quite expensive because it has a special specification. Usually, when the specifications of a laser oscillator change due to an update, the processing head must also be changed to match the specifications of the oscillator, otherwise it will become unusable and it will become necessary to design and manufacture a new processing head, fiber, etc.

Our company has experienced laser specialists on staff, so we immediately began looking into this project.

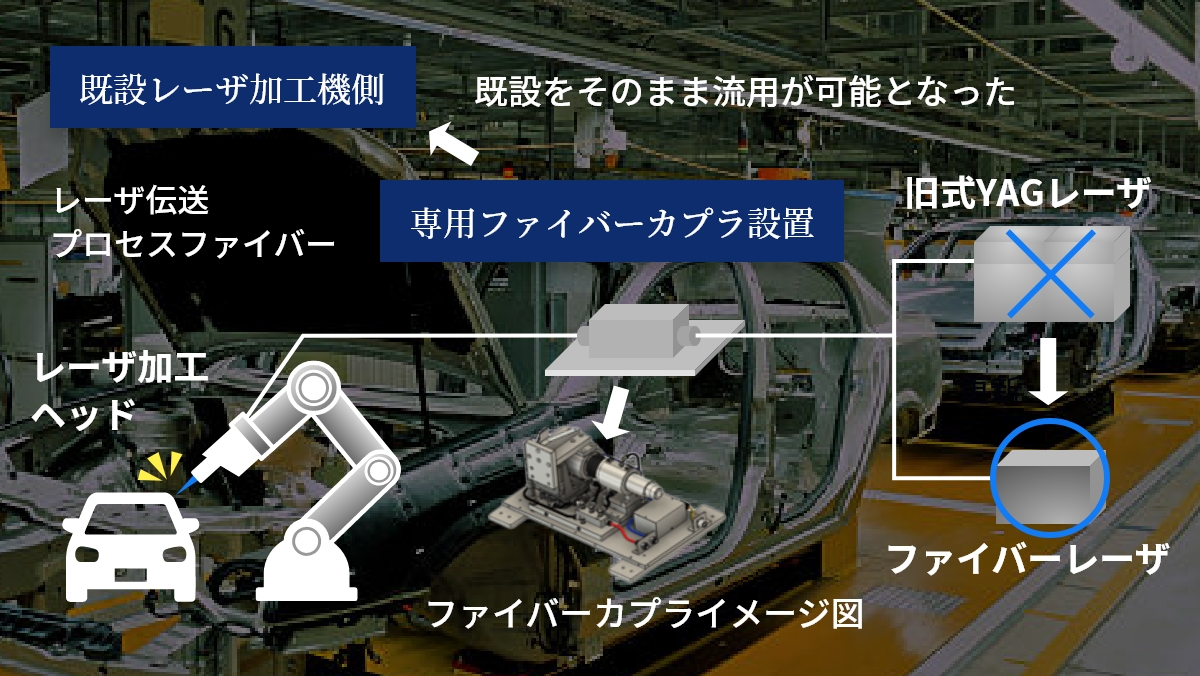

We took the time to consider how we could keep the investment costs of the entire system low by updating the laser oscillator, and were able to come up with a proposal that only our company, capable of original optical design, could make: use the existing equipment on the downstream side, such as the processing head, and only replace the laser oscillator.

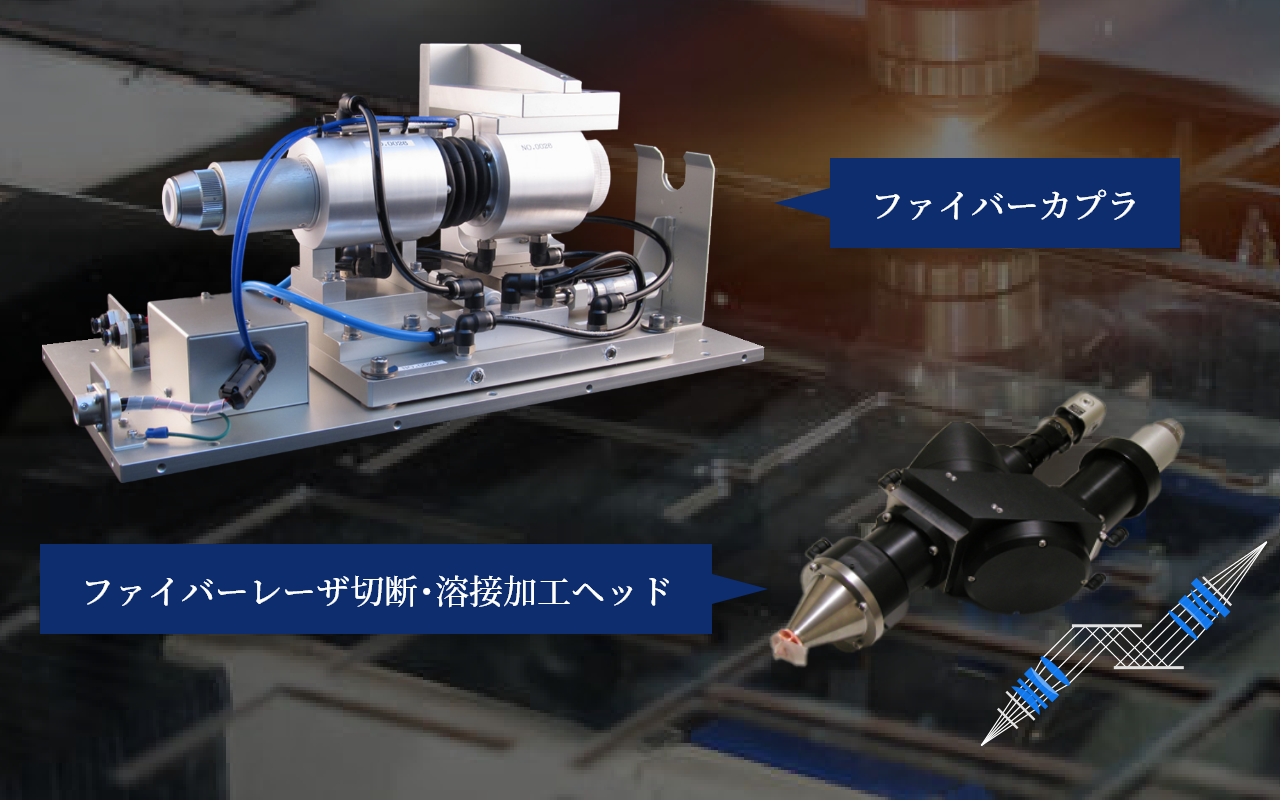

For this purpose, we proposed a device (fiber coupler) that enables optical coupling of different types of fibers with different core diameters between the laser oscillator and downstream equipment such as the processing head. However, development requires unique optical system design technology, and it is not something that anyone can easily develop. I think we were able to take on this challenge because we had engineers capable of advanced optical design.

SOLUTION

Achieved 1/3 of equipment renewal cost per unit

The customer was skeptical at first, but after several prototypes, they began to have high expectations for our technology. The first fiber optic couplers were then successfully installed, and now all similar laser welding installations have fiber optic couplers. In response to new demands to eliminate on-site adjustments after fiber insertion and removal, we have designed a dedicated alignment jig, which allows us to align products with the jig before shipping from the factory, and this allows us to significantly reduce on-site work by providing products with the optical axis already adjusted.

Systems using this fiber coupler can reduce the introduction costs for updating laser oscillator equipment to one-third of the conventional costs, and have been highly praised by many customers.

We have unique optical design technology that is not available at other companies, and are able to design and manufacture original fiber couplers, processing heads, and other optical equipment. I would like to continue proposing solutions to various issues using this technology.