BUSINESS

Vacuum System Business HS Collector

Vacuum Systems Business

Clean and high performance,a new standard for vacuum Innovationin the vacuum business

We offer a wide range of equipment, including our own HS collector series, vacuum pumps, and vacuum exhaust systems.

We use our diverse know-how and technical capabilities to solve everything from equipment orders to problems you may have at vacuum processing sites.

PICTURE

Overview of the vacuum system

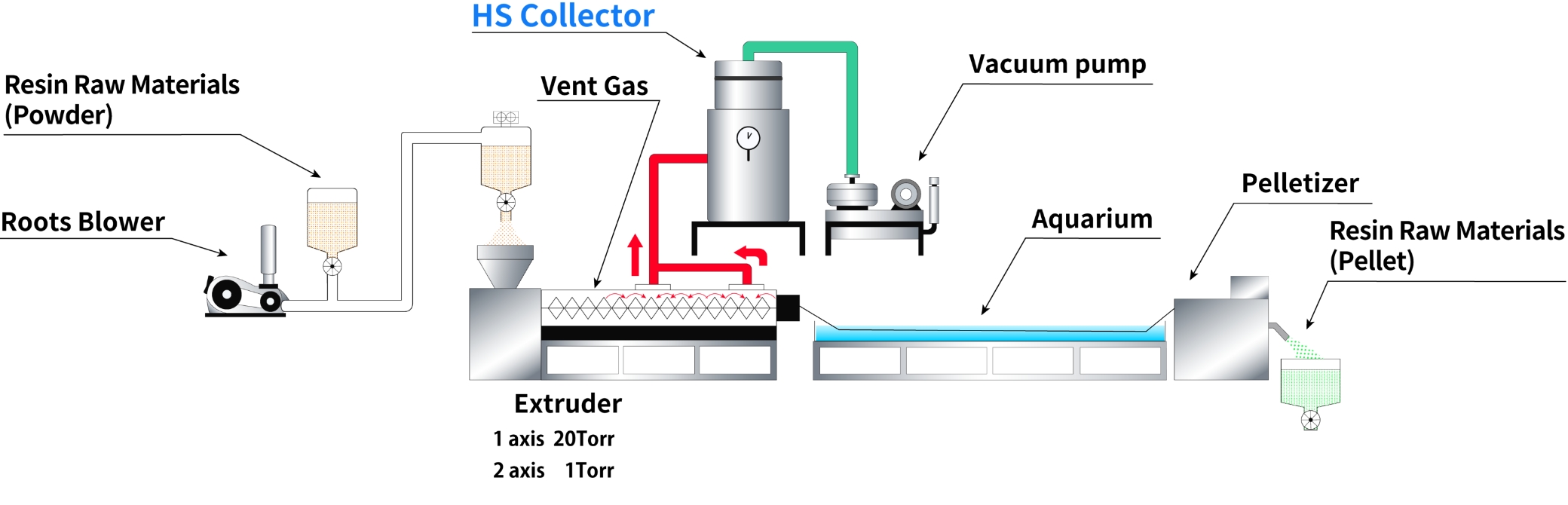

- Compounding process

-

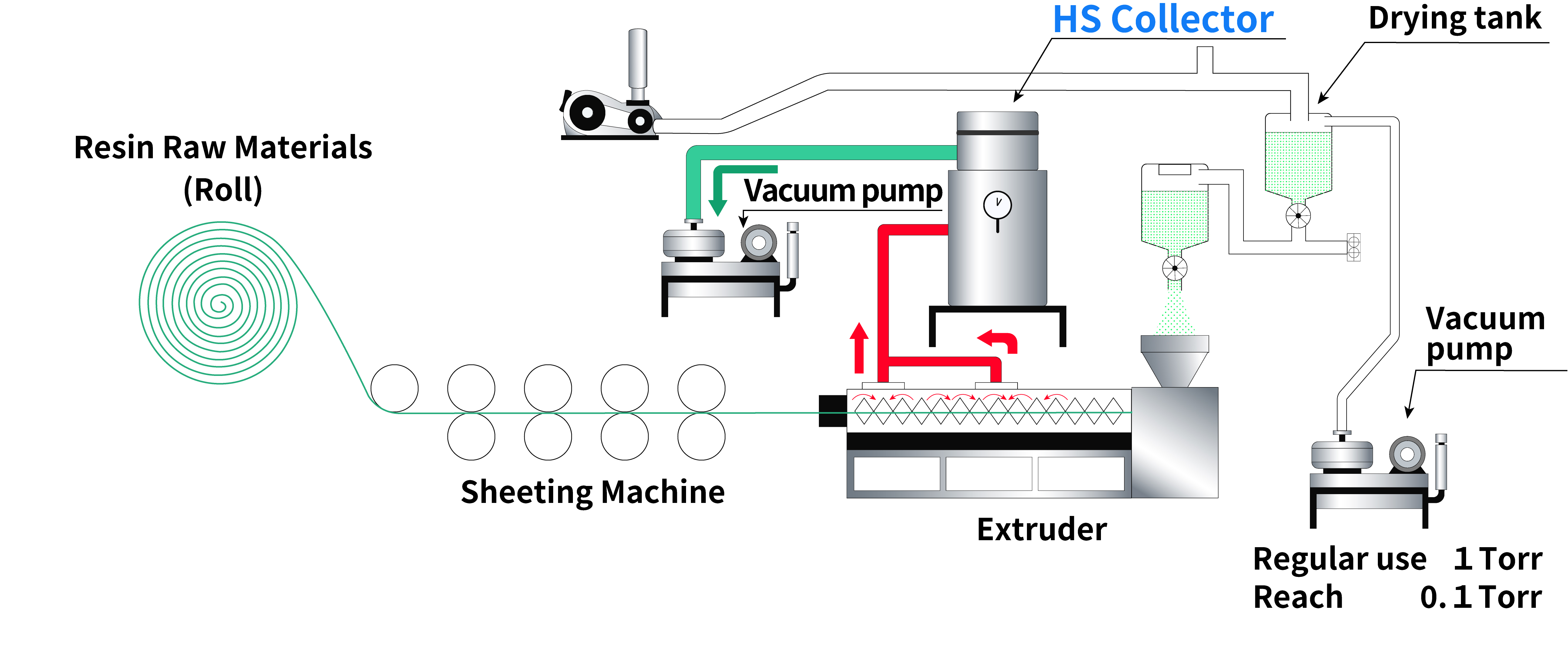

- Film manufacturing process

-

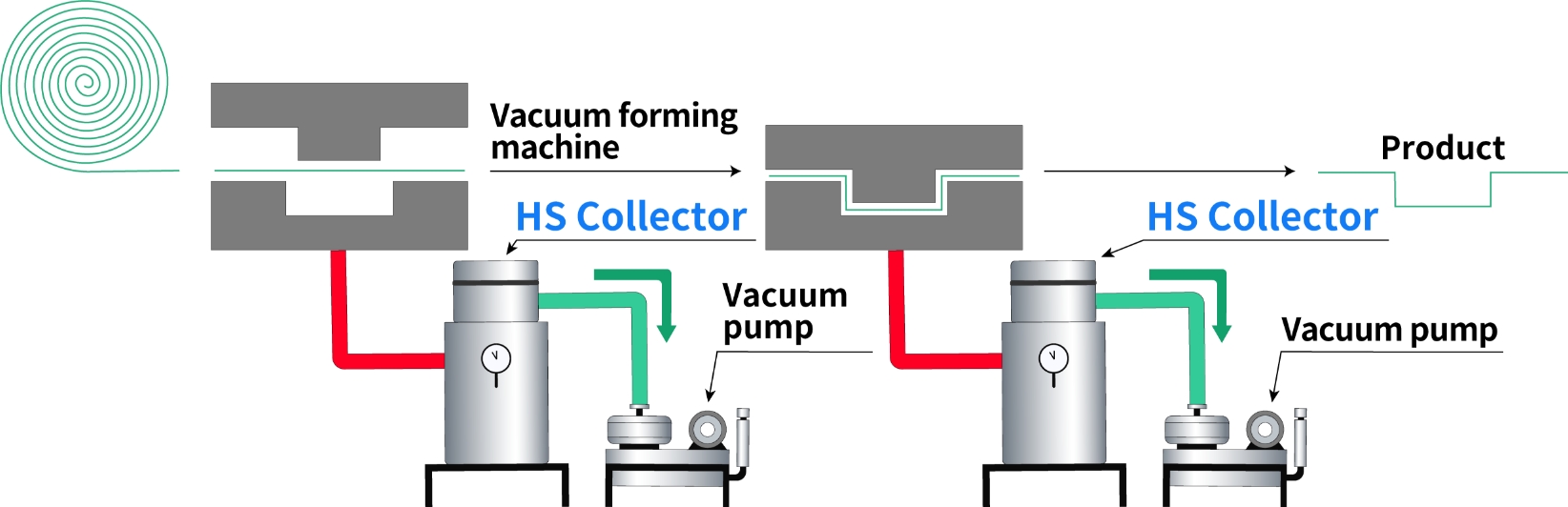

- Vacuum forming process

-

About Vacuum Pumps

There are various types of vacuum pumps.

Either model can be used without any problems if only sucking in air.

However, there are some models where simply the addition of water vapor can cause problems.

These are vacuum pumps such as oil rotary and reciprocating types.

Generally, oil rotary pumps are often used as vacuum equipment because of their low initial cost, but they are not necessarily the most suitable vacuum pump for that equipment.

Vacuum pumps used for resins, chemicals, pharmaceuticals, food, etc. mainly handle gases other than air, such as solvents, powders, vapors, monomers, oligomers, etc.

Therefore, if you select a vacuum pump that is not suitable for your application, it may cause problems and result in damage.

Even if emergency measures are taken every time a problem occurs, as long as a vacuum pump that is not suitable for the application is being used, it will not be a fundamental solution. Furthermore, if you replace the vacuum pump with one that is suitable for the application, work on the surrounding piping, etc. will also be required.

We will hold a prior consultation with you to select the vacuum pump that best suits your application from the many vacuum pump models available.

If you are having trouble with your existing vacuum pump, we will propose a vacuum pump protection device (HS collector) that is suited to the nature of the trouble and work to resolve your problem from multiple angles.

About HS Collector

- By applying the principles of condensation, collision, and cooling, it captures more than 98% of particles larger than 1μ that are vaporized, diffused, or evaporated in a vacuum.

- This prevents foreign matter from entering the dry vacuum pump, eliminating unexpected overhaul costs.

- Reduces the frequency of oil changes for oil rotary vacuum pumps and reduces waste oil disposal costs.

- Reduces water treatment costs for water ring vacuum pumps.

- Maintenance requires no special tools and the filter can be replaced in a short time.

- The HS collector has a lineup of multiple products suited to the pumping speed and amount of foreign matter mixed in by the pump.

- We can accommodate a variety of systems that combine HS collectors and vacuum pumps.

STRUCTURE

HS Collector Product Configuration

This is a clean product that is easy to maintain and has excellent chemical resistance, and is designed to efficiently capture oil mist, solvents, monomers, oligomers, etc. in dry vacuum lines.

It dramatically improves productivity in processes where vacuum pumps are used, such as vented twin-screw extrusion lines.

①Element/Microfilter

The high-performance filter is capable of capturing more than 98% of particles smaller than 1μ, making it possible to protect dry vacuum pumps, which are particularly sensitive to particles and other foreign matter.

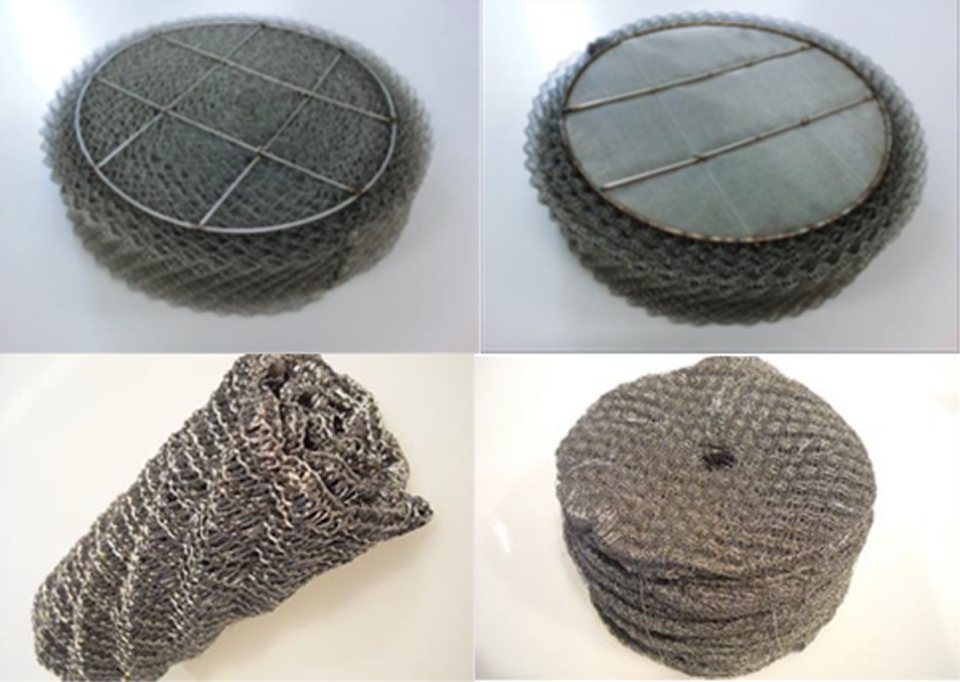

②Demister Club

When the mist is passed between the wires, capillary action occurs, causing the mist molecules to gather together, and when they reach an appropriate size, they fall under the force of gravity, capturing the fine powder.

Filters

We offer several types of high-performance filters based on the know-how we have gained from selling dry vacuum pumps for many years.

- CF-200AS

- Four-ply fiber structure used for capturing oils and liquid droplets

- Metal type

- Corrosion-resistant metal filter made of SUS304 and 316L

- MF-130 type

- Sintered metal filter for mist collection

※ The selection of each filter will be decided after consultation.

Pre-filter

It extends the life of the main filter and reduces replacement costs by wrapping it around the outside of the filter cartridge.

- Normally, clogging occurs on the surface of the filter, so by wrapping a single piece of cotton-like filter cloth around the outer periphery, you can remove more coarse particles, and by increasing the frequency of replacement, you can extend the life of the filter cartridge.

- There are two types of filter cloth: the "HS26" type, which is designed specifically for powder, and the "HS 2D" type, which removes oil, moisture (mist), etc.

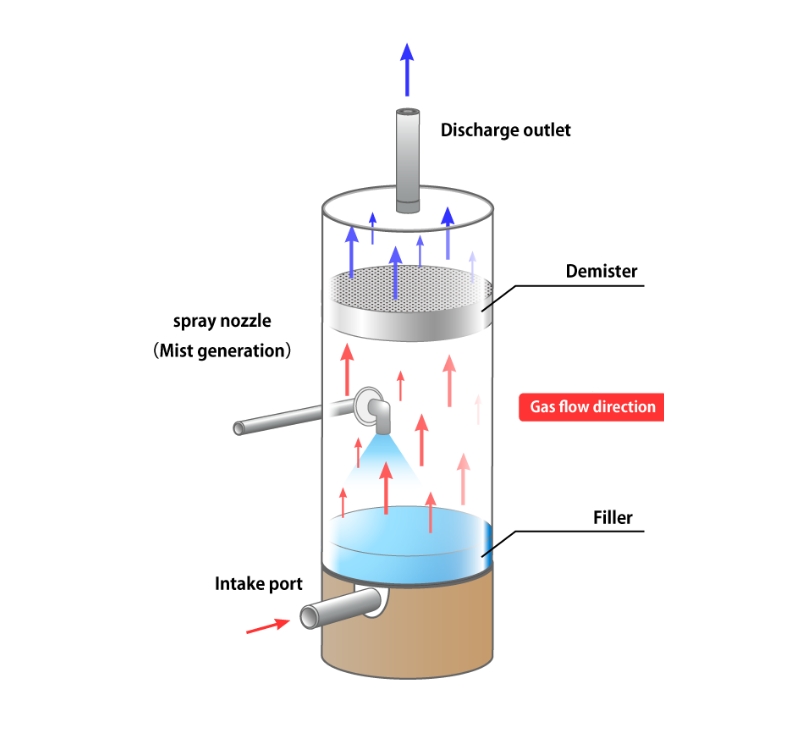

The role of the Demister

What is the Demister Effect?

The mist of oil and water is collided with a wire, causing the mist to grow into large droplets, which then fall under their own weight.

A demister is a separation promoter that makes the separation process (separative distillation) more effective.

This is a type of spray separator that collects, separates and removes impurities contained in liquids and gases using wires inside the demister.

The role of cyclones

A cyclone separator is a type of dust removal device that separates dust from a mixed-phase flow of dust or solid particles and gas, i.e., a dust-laden airflow, by centrifugal separation. Its structure is extremely simple and it has no moving parts, making maintenance and inspection easy.

In a cyclone, the centrifugal force Z acting on solid particles in the swirling air current inside the body is Z/G = 300 to 2000 times the particle's own weight G in a gravitational field, so despite its simple structure, it can produce an extremely large centrifugal effect.

LINEUP

HS Collector Product Configuration

-

HS2 -

HS2-J -

HS2-C-J -

HN2-S -

HN-B -

HC-J -

HC-F -

HA2 -

HO

| composition | type | Model | Applications |

|---|---|---|---|

| HS2 collector | Standard HS2 collector | HS2 | Can be used in a wide range of fields. Basic form of collector. |

| Jacket | HS2-J | For ABS-PC resins etc. where the recovered liquid becomes highly viscous at room temperature. | |

| Cold Tube | HS2-C-J | For hardeners and mixtures of liquid and powder. | |

| Small Collector | HN2-S | For small vacuum pumps with pumping speeds of 5m³/min or less. | |

| Large collector | HN-B | High volume version of HS. Exhaust speed 10m³/min or more. Less than 30m³/min. | |

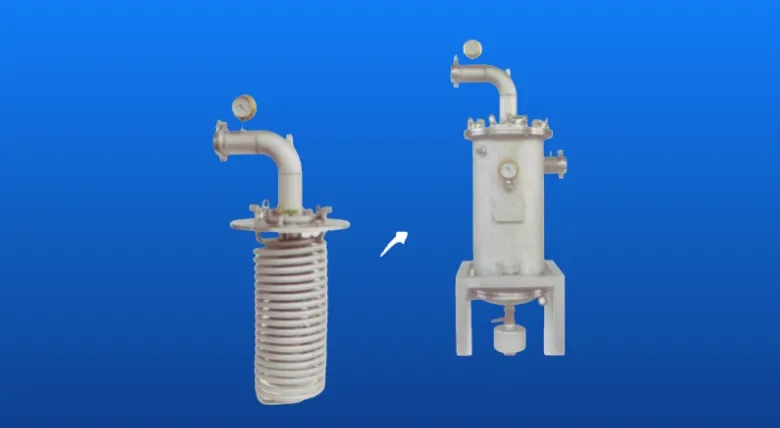

| Cold Trap | HC-J | Coolant is circulated through the internal coil to condense and collect the liquid. | |

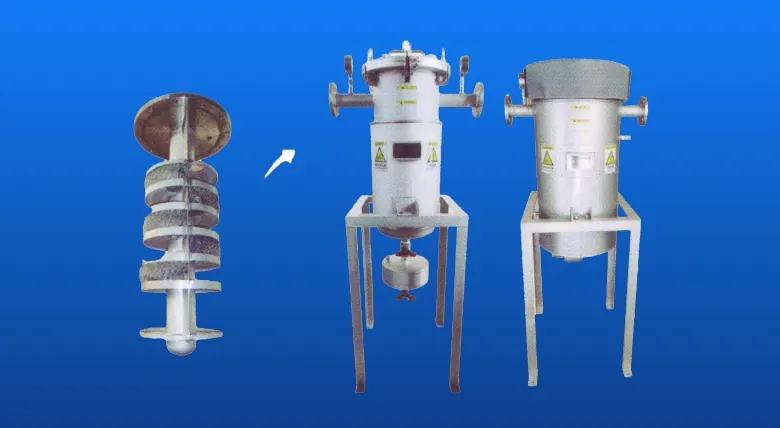

| HC-F | A highly efficient model with a demister between the cooling fins to increase the heat transfer area. For recovering solvents on the exhaust side of a vacuum pump |

||

| Simplified | HA2 | Same internal structure as HS2 type. We have reviewed the closing structure and achieved a low price. | |

| Oligomer Collector | Standard | HO | For PET resin oligomer. Can be used in powdery environments. |

CONTACT

Please contact us here for consultation.